This Article Talks About The Benefits Of Powder Coating

Utilizing Powder Coating on an auto will provide the auto a gorgeous, glossy surface. This kind of Coating is used as a completely dry powder as well as is then cured with warmth or ultraviolet light.

Electrostatic spray deposition approach

Whether you're looking for a high-performance Coating or an affordable option to liquid paints, you can find an electrostatic spray deposition method that matches your needs. The method works by applying a layer of powder to a steel substrate. It can be made use of to layer pipes, for instance, for raised toughness.

Compared to liquid applications, electrostatic spray deposition is extra long lasting and also a lot more cost-efficient. While typical damp painting can leave you with an unequal coating, this method leaves your parts smooth and also shiny.

This procedure needs the use of a specialized spray gun. official website takes advantage of compressed air to press the powder with the weapon and also out of the nozzle. This air relocates the powder along at a high rate and also atomizes the powder. It is additionally a great means to prevent clumping.

Unlike https://www.pfonline.com/articles/nordson-expand-training-offering-with-spanish-language-powder-coating-workshop , powder Coating additionally doesn't call for a solvent. It also gives a variety of coatings as well as appearances. This approach can be made use of on a variety of substratums, consisting of non-metallic products such as plastics.

Fluidized bed system

Several industries rely upon fluidized bed powder Coating to layer metal parts. This Coating supplies a thick layer of defense versus wear and rust. The procedure includes heating the part and also dipping it into the fluidized bed. The part after that moves to a reduced temperature stove for treating.

Throughout the procedure, an operator has to pay close attention to the rate of the line as well as the temperature level of the part. This is essential to keep uniform application of powder. click here now is likewise vital to keep in mind that the Coating density depends on the temperature of the part and the period it spends in the fluidized bed.

Electrostatic fluidized beds are particularly suited for continual Coating of tiny basic arrangement components. This type of Coating requires high dielectric strength and also movie density control.

Electrostatic fluidized beds are also applicable to continual Coating of wire screens. The electric area toughness of these layers is reduced. This makes them better for finishes that call for much less air circulation and also far better efficiency in Faraday cages.

Variants between liquid paint and also powder coat

Despite the differences between liquid paint and powder layer, the two completing techniques are made use of by sectors for comparable applications. Both are made use of to protect steel surface areas from oxygen and also flying particles.

The differences between both are primarily related to the application techniques. Both approaches can leave smooth finishes on a surface area, however there are several benefits to selecting one over the other.

Powder Coating is much more sturdy as well as brings a reduced carbon footprint than fluid paint. It additionally gives a variety of health benefits. It is also easier to use. Powder finishes are generally free of unpredictable organic substances (VOCs) as well as can produce thicker coats than fluid coatings.

Powder layers additionally supply a range of specialty impacts. Several of these effects consist of pearlescents, flip-flops, as well as inactive pigments.

The primary distinction in between powder as well as liquid paint is that powder Coating is applied as a dry powder, which implies that the shade does not fade. The color of a powder layer will certainly vary depending upon the polymers used to make it.

Durability

Depending on the type of Coating, powder Coating can last anywhere from fifteen to twenty years. It is utilized on a variety of surfaces consisting of steel, fiberglass, as well as some plastics. This long lasting surface secures versus the climate and also chemicals, that makes it especially useful in the building industry.

Powder Coating provides a premium surface that is resistant to damage. The Coating will certainly not chip or peel, and the colors will stay intense and also lively for longer than conventional damp painting. It is also sturdy and will withstand bumps and flexing without delaminating.

Powder Coating is much less dangerous to the environment than typical liquid paint ending up. It creates really little hazardous waste as well as releases minimal amounts of unstable organic compounds (VOCs) right into the atmosphere.

Powder Coating can be made use of to repaint family things, in addition to outdoor things like furnishings. It can additionally be made use of to protect building tools and also machinery. It is a cost-effective surface that is durable and also will certainly last for several years to find.

The Benefits And Disadvantages Of Powder Coating

Unlike standard fluid paint, powder Coating is used as a free-flowing, completely dry powder, which is then cured with heat or ultraviolet light. Additionally, https://squareblogs.net/ermelinda23azalee/allows-discusses-the-benefits-of-powder-coating-in-this-article is usually used electrostatically.

https://www.coatingsworld.com/issues/2022-10-01/view_breaking-news/akzonobel-creates-bespoke-colors-for-voloteas-10th-anniversary-livery/

Utilizing an Electrostatic spray gun for powder Coating is an excellent method to create a top quality finish on your work. This technique is utilized to develop a durable finish that can endure corrosion and cracking.

The electrostatic splashing method utilizes compressed air to deliver the powder to the work surface. The gun develops a high-voltage electrostatic area that brings in the powder bits to the steel. This develops a layer that sticks to the steel in a thick, even coat.

One of the most noticeable benefit of an Electrostatic spray gun is enhanced transfer performance. This permits a much more consistent coat, much less overspray, and less waste.

There are numerous setups to select from on your Electrostatic spray gun. Selecting the appropriate ones can improve your powder Coating efficiency. There are a few essential setups to be aware of.

The kilovolt (kV) is the device of measure for the electrostatic powder weapon cost. The higher the voltage, the even more dimples you will certainly see in your Coating. It is best to establish the voltage reduced to attain the best results.

https://squareblogs.net/charlie404tyler/allows-reviews-the-advantages-of-powder-coating-in-this-article are utilized in the manufacture of powder Coating. They are designed to offer durable finishings with a selection of colors as well as appearances. They are also an environmentally friendly option to fluid paints.

Common powder layers are formulated with a mix of pigments and also additives. These ingredients are thawed, combined, and afterwards ground into a powder. They are after that applied to the substratum utilizing electrostatic spray deposition. The powder is after that treated in a healing oven.

Powder coatings are designed to be challenging, durable, and have exceptional adhesion. They are applied to a wide array of surface areas, including plastics, metals, and also medium thickness fiberboard. Powder finishings are a cost-efficient option to standard Coating approaches. They are likewise eco-friendly, as they use less unstable organic substances (VOCs) and can be reused.

The major components of polycarbonate powder coatings are a stabilizer, progressing representatives, and crosslinking resin. These active ingredients need to be thoroughly regulated to ensure proper diffusion and also optimum circulation. In addition, the surface stress of the Coating must be maintained low to reduce film defects.

Surface areas that can be covered

Using powder Coating to layer surface areas can be a cost-effective option to wet paint. Besides being more economical, it can be less complicated to keep as well as tidy. On top of that, it is eco-friendly. It fends off corrosive products as well as has a wide range of coatings.

Powder Coating can be utilized on a range of surface areas, consisting of plastics, metal, and also glass. Its durable coating makes it an excellent choice for architectural applications. Nonetheless, it does have its limitations.

Some metals can not be powder coated. For instance, certain fillers can't withstand the heats of the curing procedure. Also, glass is a difficult product to powder coat.

In addition to the fact that it's environmentally friendly, powder Coating is also an exceptional protective Coating. This surface withstands scrapes and abrasions and provides an easy-to-clean finish.

Although it isn't the most convenient to clean, powder covered things can be easily brought back with a soft brush and also a little of moderate soap in water. Use filtered water for finest results.

Downsides

Using powder Coating for completing commercial items has many benefits, yet it additionally has its downsides. These include high startup costs, restricted color range, and also difficulties applying a slim coat. Despite these disadvantages, powder layers offer a resilient finish and also are resistant to scratches.

Powder coatings are environmentally friendly. They have very reduced emissions of volatile natural substances, or VOCs. They additionally have less carbon dioxide exhausts and are much more efficient in paint usage. They likewise remove the need for pricey air pollution control tools.

Powder Coating also has the advantage of being much easier to clean up. Nonetheless, it is essential to maintain the spray booth location tidy between shade changes. If the cubicle is not cleaned up properly, it can bring about cross-contamination.

Powder Coating can also chip or flake off in particular problems. This can be due to incorrect prep work, or even as a result of rust. Because of this, it is essential to avoid storage problems that enable moisture to collect externally. Also, powder Coating can break down if it is subjected to UV light.

Powder Coating - Safeguard Your Metal Objects From Rust

Whether you want a coat of paint or you intend to make a face-lift for your office or home, there are various kinds of layers offered. Powder Coating is one kind of Coating that you may want to consider. Unlike standard fluid paint, powder Coating can be used as a free-flowing dry powder and also treated with heat or ultraviolet light.

https://writeablog.net/tequila83louetta/here-is-a-more-detailed-look-at-what-is-powder-coating

Utilizing electrostatic spray deposition to apply a powder Coating to a non-metallic part can be an efficient way to secure the underlying material from rust. Using the appropriate procedure will enable an even application as well as a smooth surface.

The powder Coating process entails a chemical reaction which produces lengthy molecular chains. The molecular chains are very resilient and resist breakdown. The chain reaction additionally creates a smooth coating.

There are relevant webpage to use powder Coating. To start with, using an electrostatic spray gun. This approach is frequently referred to as dipping.

The other method is making use of a fluidised bed. Utilizing this technique involves dipping the part into a fluidized powder. The powder is after that sprayed using a high-powered electrostatic spray gun.

Both techniques are fairly cost-effective and give an also, hard coating. They are likewise extra sturdy than liquid applications. This is due to the fact that the spray gun makes use of high-voltage to compel the powder right into the part.

Fluidized bed powder Coating technique

Primarily, the fluidized bed powder Coating technique is a process in which a part is preheated and afterwards dipped into a fluidized bed of put on hold powder. The powder follows the part by electrostatic pressures. This procedure is generally utilized for finishes with high permeability materials.

Normal application techniques consist of the dry powder Coating approach as well as electrostatic spray deposition. These methods offer numerous benefits over fluid coatings. They are cost-effective and also produce a thicker Coating. The thickness of the Coating depends on the powder chemistry and the dwell time.

The powder Coating process utilizes finely ground pigment or polymeric resin to use a layer. It additionally uses a redeemed powder to boost powder Coating transfer effectiveness. It can be related to a large range of items.

It can be made use of for Coating steel superstructures. It also functions well for Coating little products. It is also advantageous for Coating components that are vulnerable to rust.

Masking items are applied

Numerous masking items are made use of in the powder Coating procedure. These items are developed to shield parts from the application procedure. Additionally, these products can be made use of to mask areas that are not needed to receive powder Coating. simply click the next web page can be mating surfaces or electric conductivity.

One of the most common masking product used is high temperature polyester tape. These tapes are created to be made use of in the powder Coating procedure as well as are immune to severe cure temperatures. These tapes are offered in a variety of sizes and shapes. They can be bought on a roll or pre-cut.

One more typical powder Coating concealing item is silicone. This sort of concealing product is resistant to heats as well as can be utilized in applications that need aggressive chemicals. Additionally, it has a sticky that is immune to high temperatures and can be quickly eliminated after high warm processes.

Other masking products include cork as well as paper. Cork can be made use of in reduced temperature level finishing procedures. Nonetheless, these products are not as adaptable as silicone or neoprene tapered plugs.

Toughness

Making use of powder Coating on your metal things permits them to be immune to rust, weather condition, and chemicals. It also helps them last much longer. Generally, these coverings will certainly last approximately twenty years.

The longevity of powder Coating is determined by the kind of material used as well as the application technique. Furthermore, the quality of the coating is also a variable. It is important to make certain that the materials are tidy and are in conformity with neighborhood codes.

Powder coated items are normally a lot more immune to rust, chips, as well as scratches. They also withstand deterioration far better than various other treatments.

Powder Coating is an economical alternative for lots of jobs. It is offered in a wide variety of shades and also textures. It is additionally eco-friendly. Contrasted to fluid paint completing, powder Coating utilizes much less hazardous waste and also launches very little VOCs into the environment.

Powder Coating is additionally used to layer numerous common family items, consisting of devices, household pipelines, and also kitchen area surface areas. It is additionally used on a variety of building jobs. It likewise provides a resilient coating that can last up to a decade in good conditions.

Here Are The Benefits Of Powder Coating

Unlike fluid paint, which is delivered with evaporating solvent, powder Coating is used as a free-flowing dry powder, then cured with warm or ultraviolet light. Powder Coating is related to surface areas in order to protect them from environmental damages and scratches.

Pretreatment

Getting an exceptional pretreatment prior to powder Coating is a must to obtain a long lasting, corrosion immune Coating. Along with boosting the adhesion of the powder to the substratum, it additionally provides the steel with a protective layer.

The procedure can be a dip, spray, or a combination of several techniques. The option of procedure depends upon the type of item being covered as well as the client's specifications. The efficiency of the pretreatment have to be matched to the requirements of the powder layer, along with the products used in the pretreatment.

The first step in preparing a component for powder Coating is to eliminate surface area soils. Some common approaches consist of stress washing, sandblasting, and also innovative media blowing up. The quantity of soil that requires to be removed will vary depending on the sort of item being covered.

Electrostatic spray deposition method

Using electrostatic spray deposition, a powder mix is splashed onto a metal surface. The electrostatic destination in between the powder bits and the steel surface area results in a finish that protects the underlying product from corrosion. This Coating offers a range of coatings as well as textures. The Coating is additionally readily available in a number of colors.

The electrostatic spray deposition procedure includes the use of an electrostatic spray gun as well as a powder spray booth. This system is a common method of applying powder finishings. A corona spray gun is an usual electrostatic spray gun. The electrostatic spray gun contains a nozzle that produces high voltage to create an electrostatic field between the metal foil as well as the spray mix. The powder blend is then splashed via the nozzle to the metal surface.

Fluidized bed powder Coating approach

Unlike standard liquid finishings, the Fluidized bed powder Coating method is extra environmentally friendly. It is also a lot more economical. It offers a hard, smooth surface with excellent toughness. It can be applied to different things such as steel superstructures, covering equipment, and airplane elements.

Fluidized bed powder Coating method is likewise utilized on different components that undergo heats. It safeguards the component against rust as well as ecological effects. It also smooths over small details. During the process, parts are preheated and after that dipped into a "fluidized bed" of plastic powder. Later, the components are healed in an oven. This kind of Coating is optimal for parts with Faraday cage results.

Unlike liquid layers, the Fluidized bed powder technique creates heavy layers in one dip. This sort of Coating method has high transfer performance. https://zenwriting.net/ivan150gena/powder-coating-shield-your-steel-objects-from-corrosion eliminates the demand for overspray healing systems.

Cross-contamination

Making use of powder Coating to coat a product can be very effective. However, it is essential to make use of the right powder and also to comply with good contamination control methods to guarantee a top quality coating.

Cross-contamination happens when a part or powder is revealed to contaminants such as dust, dirt, oil, and metal chips. Completion result might be a problem in the finish, which might result in a dissatisfied customer.

The smallest speck of dirt might spoil a powder covered item. Because of this, it is necessary to make sure that the powder and also the air in the powder Coating space are clean. industrial powder coatings santa clarita is likewise important to make sure that the space is well filteringed system. This will certainly make certain that the dirt from the remainder of the building is not able to penetrate the powder Coating area.

Toughness

Among the many benefits of powder Coating is its longevity. It is used on a wide variety of items. It gives resistance to impact, abrasion, deterioration, and also chemicals. It can last for many years, even decades, if it is applied correctly.

Powder Coating is likewise less damaging to the environment than traditional liquid paint finishing. It releases minimal quantities of unpredictable organic substances (VOCs) into the atmosphere. It is also easy to tidy. It is quickly washed with warm water.

Powder Coating provides a large range of textures, from smooth surfaces to rough textures. linked web-site is likewise readily available in a variety of surfaces, from shiny to matte.

Powder Coating can hold up against smog, UV radiation, and acidic conditions. It is additionally extremely immune to corrosion, chipping, and climate. It can be put on several types of products, such as metal, plastic, and also glass. It is extensively made use of in numerous sectors, including building and construction, agriculture, electric engineering, and also the manufacturing of mechanical parts.

Here Is A Closer Check Out What Is Powder Coating?

Normally, the term powder Coating describes a type of Coating that is applied as free-flowing dry powder, then healed with warm or ultraviolet light. This kind of Coating is different from traditional liquid paint, which is provided using vaporizing solvents.

Preparation of powder Coating components

Getting your powder covered parts ready is a process. It entails a collection of actions that can range from simple to elaborate. If you want to make sure that your finished item is excellent, you have to be sure to adhere to the right actions.

The primary step is to get rid of any kind of dust, dirt and other surface area impurities. You can use a stress washer or merely soak the components in tidy water.

The following step is to sandblast the surface area to get rid of any type of imperfections and also provide appearance. This is also essential to ensure that the powder coat adheres properly. Sandblasting can be carried out with a range of rough media. Picking a tidy sandblasting media is important to guarantee an effective powder coat.

The powder coat procedure entails the application of a polymer combined with pigments. This is then healed in a healing stove. The procedure is reasonably easy and low-cost. Relying on the component dimension, the healing time will vary. The temperature level should be established according to the maker's specs.

One of the most essential action is the pre-treatment. This is the most effective method to ensure that your powder coat is applied effectively. discover this entails eliminating oil from steel pores, getting rid of any kind of paint that may be remaining externally, and also cleaning the surface area of dirt and gunk.

Environmentally friendly option to solvent-laden paints

Utilizing an environmentally friendly alternative to solvent-laden paints is now a feasible alternative. For wheels powder coating santa clarita , you can replace toxic paints with environment-friendly ones that are free of unsafe chemicals.

These paints are not only healthier for the atmosphere, but they can also conserve you money over time. They can conserve you 5 to $11 per automobile. They additionally assist you reduce exhausts, which suggests less carbon dioxide airborne.

Among the most effective eco-friendly alternatives to solvent-laden paints is latex paint. They have a lower VOC content as well as do not give off a scent like various other paints. They can likewise be an excellent selection for LEED credit reports.

An additional environmentally friendly paint is one that utilizes metals as pigments. Paints that make use of metals in the pigment can be much safer than chemical pigments.

Several companies have collaborated to make items that are both reduced in VOCs and also high in safety. One of these business is ECOS Paints. They offer a range of paints, varnishes, and also discolorations. They are made from natural active ingredients and are free of hazardous chemicals. They are packaged with biodegradable product packaging and also 100% recycled plastic.

They are additionally accredited by the Eco-friendly Seal program, which restricts the damaging chemicals in their items. Another option is Colorhouse. They have a beautiful choice of shades and also highlight sustainability and also recycling. They likewise make use of metals as well as dangerous components as minimally as feasible. They are likewise LEED Compliant as well as MPI Extreme Environment-friendly accredited.

Can be recuperated as well as reused

Utilizing powder layers can reduce the environmental influences of using solvents. Powder Coating systems additionally minimize costs associated with the risk-free disposal of unpredictable organic compounds. Powder finishes are made use of in many markets. They are durable and immune to rust as well as fading. They are likewise available in a wide range of shades, gloss degrees, and textures.

The powder Coating process enables components to be delivered right away after healing. This minimizes the quantity of time that parts spend in supply. It additionally aids to reduce waste.

The most efficient method to reuse powder overspray is by recuperating it. Healing systems can reclaim approximately 98 percent of the overspray. This is a fantastic method to minimize waste and also conserve cash.

A powder healing system is consisted of a recovery cubicle, a collector, as well as filters. The collection agency will certainly collect overspray from the healing cubicle. It will certainly after that be carried to a feed hopper. Some feed receptacles will vibrate to aid prevent powder clumping.

Recovery systems will not always return the exact same proportion of base to effect as virgin powder. Furthermore, some powder may be lost in the collection filters. Utilizing a cartridge-style filtration system will decrease the quantity of destruction of the powder.

The recuperation procedure can additionally raise step-by-step efficiency. For example, it can permit components to be stacked more detailed with each other on a conveyor. https://lakia45lashaunda.bravejournal.net/post/2022/11/28/Powder-Coating-Just-How-To-Apply-Multi-Color-Powder-Coatings can additionally permit even more parts to travel through the assembly line in less time.

This Short Article Talks About The Benefits Of Powder Coating

Making Use Of Powder Coating on an automobile will certainly provide the car an attractive, glossy surface. This type of Coating is used as a dry powder and also is then healed with heat or ultraviolet light.

Electrostatic spray deposition technique

Whether you're searching for a high-performance Coating or a cost-effective choice to fluid paints, you can find an electrostatic spray deposition technique that suits your demands. The method functions by applying a layer of powder to a steel substratum. It can be made use of to layer pipes, for instance, for boosted resilience.

Contrasted to fluid applications, electrostatic spray deposition is extra durable and also extra economical. While conventional damp paint can leave you with an uneven finish, this approach leaves your components smooth as well as shiny.

powder coating santa clarita, los angeles county

This process needs the use of a specialized spray gun. It also takes advantage of compressed air to press the powder with the weapon and out of the nozzle. This air moves the powder along at a high price as well as atomizes the powder. It is likewise a fantastic way to stop clumping.

Unlike traditional damp paint, powder Coating additionally does not call for a solvent. It likewise offers a range of finishes and also appearances. This technique can be used on a range of substrates, including non-metallic products such as plastics.

Fluidized bed system

A number of markets count on fluidized bed powder Coating to coat metal components. This Coating supplies a thick layer of protection versus wear and also rust. The procedure involves warming the part and also dipping it right into the fluidized bed. The component then relocates to a lower temperature level oven for treating.

Throughout the procedure, an operator should pay attention to the speed of the line and also the temperature level of the component. This is required to keep consistent application of powder. It is likewise crucial to keep in mind that the Coating density is dependent on the temperature level of the part as well as the duration it spends in the fluidized bed.

Electrostatic fluidized beds are specifically fit for continual Coating of tiny straightforward configuration parts. This type of Coating calls for high dielectric stamina and also movie density control.

Electrostatic fluidized beds are also relevant to continuous Coating of wire screens. The electric area toughness of these coverings is lower. This makes them more suitable for finishes that need less air circulation as well as far better performance in Faraday cages.

Variations in between fluid paint as well as powder layer

Regardless of the differences between fluid paint as well as powder coat, both completing approaches are used by industries for similar applications. Both are utilized to protect metal surface areas from oxygen and flying debris.

The differences in between the two are largely related to the application methods. Both methods can leave smooth finishes on a surface area, however there are numerous benefits to picking one over the other.

Powder Coating is extra long lasting and also brings a lower carbon footprint than liquid paint. It likewise supplies a number of health advantages. It is also less complicated to use. Powder coverings are normally without unstable natural compounds (VOCs) and can create thicker coats than liquid coverings.

Powder finishes additionally use a range of specialized results. A few of these results include pearlescents, flip-flops, as well as inactive pigments.

simply click the next internet page in between powder and fluid paint is that powder Coating is used as a dry powder, which indicates that the color does not discolor. The color of a powder coat will certainly differ depending upon the polymers used to make it.

Durability

Depending on the kind of Coating, powder Coating can last anywhere from fifteen to twenty years. It is used on a variety of surfaces including metal, fiberglass, and some plastics. This durable surface secures against the weather condition and also chemicals, that makes it particularly beneficial in the building market.

Powder Coating offers a top notch coating that is immune to damage. The Coating will certainly not chip or peel, as well as the shades will remain intense as well as dynamic for longer than traditional wet paint. It is additionally long lasting as well as will certainly stand up to bumps as well as flexing without delaminating.

Powder Coating is much less unsafe to the environment than typical liquid paint finishing. It generates very little hazardous waste and also releases minimal quantities of unstable organic substances (VOCs) right into the atmosphere.

Powder Coating can be made use of to repaint family things, as well as outside items like furnishings. It can additionally be utilized to protect construction devices and also machinery. It is an economical surface that is durable and also will last for several years to come.

Let'S Goes Over The Benefits Of Powder Coating In This Article

Unlike liquid paint, powder Coating is used as free-flowing completely dry powder and after that healed with warm or ultraviolet light. The powder is usually used electrostatically.

Pretreatments

Having a pretreatment on a product prior to applying a powder layer is necessary for many reasons. In addition to preventing deterioration, it will certainly likewise enhance the longevity of the Coating. Getting https://www.coatingsworld.com/issues/2022-06-01/view_breaking-news/extreme-coatings-launches-new-inner-diameter-hvof-coating-for-oil-gas-industry/ will additionally help you avoid any possible personal dangers.

The pretreatment procedure starts with cleaning up the surface. Normally, this is done with a cleansing solution splashed onto the substratum. This gets rid of the surface area soils and also dirt, thus making it possible for the powder coat to stick more effectively.

In addition to cleaning, the pretreatment procedure also includes preparing the surface area for the powder layer. This consists of adding a phosphate layer, a chemically adhered substance that helps to enhance the Coating. The phosphate layer assists stop oxidation on the surface. It is likewise a great suggestion to coat the item with a clear film to safeguard it from UV rays.

An additional technique of pretreatment is chemical etching. Unlike the traditional procedure, this process does not need manual work. It is also an inexpensive method. The process uses chemicals to get rid of surface dirt, grease as well as various other impurities.

Kinds of powder Coating cubicles

Whether you're seeking a powder spray paint booth for a big or small application, there are numerous different types to select from. Each sort of powder spray cubicle has advantages and also negative aspects.

When making a decision which type of powder spray paint booth is right for you, you must consider the size and quantity of parts that you're Coating. This will identify the air circulation needed for your powder control. Powder spray booths are available in different sizes as well as can be either open-faced or closed-faced.

For huge tools ending up applications, powder Coating booths are a great solution. They supply reliable air flow and also enable shade changes throughout the procedure. They also give a tidy area for powder Coating, keeping the rest of your store clean.

An additional advantage of powder spray booths is that they have a built-in filtering system. The filtration can be built into the flooring or walls, depending upon your requirements. HEPA filters are often made use of to catch bits. They additionally permit exhaust to be directed back right into your shop.

Methods of application

Depending upon the sort of product that you are Coating, there are different approaches of application. These include electrostatic spray deposition, fluidized bed dipping and "warm crowding" (electrostatic spray on preheated surfaces).

Electrostatic spray deposition is the most usual approach of applying powder Coating to steel. A special electrostatic gun is used to spray the powder onto a grounded metal surface. Depending upon the sort of Coating that you are applying, you might also require a power device and also a powder spray booth.

Compared to conventional paint, powder Coating is much more long lasting as well as eco-friendly. It is likewise affordable. It can be made use of on a variety of surface areas consisting of metal, timber, as well as plastic.

Fluidized bed powder Coating was patented in 1953 by Edwin Gemmer. It utilizes the very same fluidising principles as a conventional fluidized bed, but without the need for pre-heating. It was established to apply slim films with consistent fragment dimension.

The powder Coating procedure likewise uses benefits to coaters. These consist of price savings and also very little driver training. The powder is sprayed onto a substrate, which is then cured. The completed item can have a matte or shiny surface. Depending upon the dimension and thickness of the component, a film can be applied in density from 8 to 125 millimeters.

Disadvantages

Whether you're aiming to secure your wheels from damages or just maintain them looking new, powder Coating can be a wonderful option. It's not only cost effective and also easy to apply, yet it also has a selection of benefits.

Powder Coating has great mechanical homes as well as a long lasting surface area coating. It is likewise extremely resistant to damaging, damaging, and also fading. Its surface can last as long as two decades on steels, as well as as much as 10 years on timber.

Powder Coating can be utilized to secure several steels and surfaces. It's an affordable alternative to repaint, and also it's likewise less flammable than solvent-based fluid finishes. Nevertheless, powder Coating has its own set of disadvantages.

Powder Coating has issues with color matching and also leveling. It can likewise be tough to retouch areas that have actually been missed. It's additionally challenging to accomplish a thin film build. It also has problems removing spots.

powder coating santa clarita, los angeles county

Powder coated light weight aluminum is less costly than standard paint remedies. It's additionally more immune to chemicals, UV exposure, and wetness.

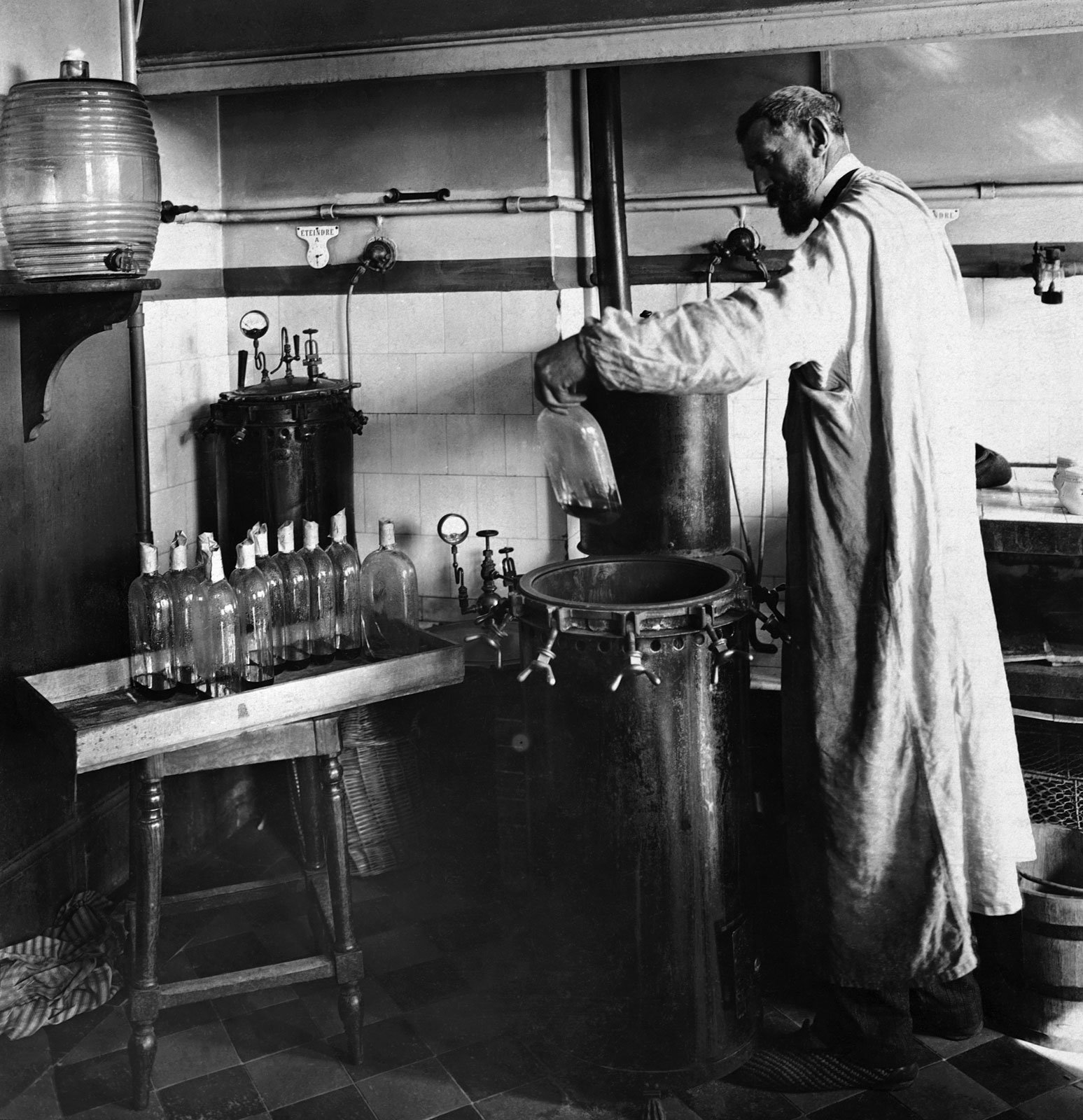

Continue Reading To Find Out More Information Regarding Tunnel Pasteurizers For Beer & Drink Makers

Tunnel Pasteurizers make use of high temperature to safely refine food and also various other products. The procedure uses various areas where water is splashed in order to heat and cool down the item being pasteurized. In some equipments, the temperature level of the water is checked, which makes sure the procedure is functioning correctly. Tunnel Pasteurizers can be utilized in a large range of applications.

Tunnel Pasteurizers are utilized to safely and also regularly pasteurize packaged drinks, such as beer and also white wine. These makers use a conveyor to move the packages through a long, narrow Tunnel. The Tunnel is commonly 15 to 30 meters long as well as is comprised of numerous temperature level areas. The first area is the heating zone, as well as the 2nd zone is the holding or cooling down zone. Throughout the process, water is sprayed onto the containers and also bottles.

Tunnel Pasteurizers can produce items with increased shelf life by shutting down enzymes and also microbes. Modern Tunnel pasteurizers save power by using sophisticated innovation. The style of these devices enables a modular setup, which helps in reducing setup costs. They likewise include continuous belts made of polypropylene or stainless steel. The home heating as well as cooling procedure is controlled by a PLC. If you require a pasteurizer for your production line, you can speak to Diversey to get more information concerning what is offered in your area.

The Tunnel Pasteurizer display is a software and also equipment system that checks the pasteurization process and manages the water spraying inside the Tunnel. It additionally has an integrated temperature sensor that gauges the temperature and also time of each private section. This information is crucial in determining the pasteurisation devices. Tunnel Pasteurizers are an excellent choice for pasteurizing many items. So, consider them if you are seeking an excellent quality, trusted pasteurizer.

Tunnel Pasteurizers are effective devices that get rid of recurring microorganisms from food and also beverage items. The HT205 mini Tunnel pasteurizer provides flexible specifications that allow the driver to replicate a large range of full-blown manufacturing situations. It likewise conserves water and power, which are both vital components for a production line.

Tunnel Pasteurizers are normally constructed from stainless steel, and they come in various sizes as well as measurements. This permits them to be tailored to the specific food types as well as processes that you generate. Besides being easy to use, they additionally do not wreck the flavor or texture of the item. They also come with automatic-stop mechanisms that avoid overpasteurization.

There is an area for pasteurization in little breweries as well. The procedure can preserve the flavor of beer even if it is produced in a little range brewery. Small breweries are significantly realizing the value of pasteurization and are carrying out the modern technology to make craft developing a success.

The Tunnel pasteurizer can warm milk at a price of 363 kilograms per hour. In https://www.inverse.com/article/59928-raw-milk-health-benefits-pasteurized-vs-unpasteurized of situations, the milk is cooled down pull back to 4.5 degC. A positive variation pump increases the stress on milk leaving the regeneration area, causing a pressure differential of 41.4 kPa over the feed or raw side of the regrowth system. The MST sterilized milk has a shelf life of approximately 60 days at 4 degC, and also the complete decrease of germs is greater than five log cycles.

There Are A Couple Of Crucial Considerations To Consider Prior To Acquiring A Tunnel Pasteurizer

Passage Pasteurizers are highly helpful in industries where the production of big amounts of pasteurized items is called for. These equipments operate on the exact same concept, pasteurizing food at heats and also keeping them in an amazing, dry setting. Tunnel Pasteurizers are usually incorporated right into a bottling or classifying line. This indicates that the process is highly efficient and also does not require any special expertise or skills. There are various types of passage pasteurizers.

For beer manufacturing, Tunnel Pasteurizers can be especially valuable for speeding up the procedure. Their temperature level arrays are controlled, unlike other approaches which are largely trial and error. Consequently, an extensive understanding of pasteurization processes will certainly assist make certain taste stability as well as defense against contamination. Passage Pasteurizers have the advantage of guaranteeing constant results, making them an excellent selection for a house brewery.

A Tunnel system need to be developed to supply ideal thermal treatment. Commonly, tunnel systems will certainly be constructed as modular or monoblock structures. Some models can pasteurize wine, juice, beer, or lightly carbonated drinks. The tunnel system is created from stainless-steel and consists of a number of procedure containers. The tunnel can be single-deck or multi-deck. Numerous elements, such as valves, warm exchangers, and also circulating pumps, are mounted on the exterior of the passage.

Craft Tunnel Pasteurizers are created for small to medium-sized breweries. They consist of the same performance as their bigger brother or sisters, but in a monoblock layout. Its totally automated as well as advanced pasteurization process makes it a wise option for tiny and medium-sized brewers. They are also highly effective. If you are trying to find a reliable, cost-efficient equipment to warm up your drinks, take into consideration the adhering to suggestions.

The set pasteurizer system includes a stainless-steel drum, a stainless-steel funnel, and also a closed cover. These systems are wonderful for house use, and also the majority of designs can be linked to a standard wall outlet. Tunnel Pasteurizers are easy to use and budget-friendly. If you are taking into consideration purchasing one for your residence or commercial cooking area, it is necessary to consider the price. And as the price of these equipments is relatively reduced, they are an exceptional investment.

The service life of foods is a crucial parameter to take into consideration. Natural toughness is just a few days, which is why manufacturers often include chemicals as well as thermal processing to lengthen its life span. Tunnel Pasteurizers enable ideal use thermal power while saving health food. The modular design allows for future expansion and also much easier distribution. With these advantages, it's no wonder that Tunnel Pasteurizers are popular with manufacturers and also food processing industries.

Other than prolonging the service life of drinks, pasteurised foods items can additionally create some quality issues. Relying on the water chemistry of the tunnel pasteuriser, these things might suffer from rust-like spots on their crowns, staining of aluminium can base domes, and fading of unlacquered containers. In addition, inorganic salts might precipitate and trigger unsightly spotting on the bundle.

Prior to the advancement of Tunnel Pasteurizers, the process of pasteurization was thought to be the domain name of industrial beer breweries. Independent breweries were reluctant to adopt pasteurization since it gave up flavor for shelf-stability. Nonetheless, as time passed as well as the craft beer industry expanded, national brand names came to be more prevalent, meaning even more containers took a trip additionally. Moreover, brewing link web page evolved as well as became more adventurous, consisting of barrel aging. As the microbial load of the beer raised, its shelf-stability additionally lowered. This minimized the money and customer confidence of brewers.

Continue Reading For More Information Regarding Tunnel & Batch Pasteurizers - Beer & Drink Makers

The Tunnel & Batch Pasteurizer series combines the most effective of both globes. The product line makes use of high boiling temperature levels to sanitize active components while also stopping damage to heating pipelines. Read Much more boiling point allows it to keep its preliminary temperature level throughout the entire assembly line, so you don't need to worry about occluding warm exchangers or endangering the item's security.

The fundamental system features a glass carafe, stainless-steel drum, stainless-steel pipeline, and also a condenser. Many systems consist of individual handbooks and link into a typical wall outlet. The pre-heated paddle top is after that positioned in the closed drum. When the procedure is full, the system features a closed cover and pre-heated condenser. These gadgets can be conveniently made use of in the cooking area as well as can be connected to a typical electrical outlet.

“CBD-INFUSED PRODUCTS PASTEURIZATION”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) August 2, 2022

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article:https://t.co/C6X48CPcS2

PRO Engineering / Manufacturing, Inc

414-362-1500 pic.twitter.com/JGqlDHXins

The Tunnel & Batch Pasteurizers include a stainless steel drum, a pre-heated glass bottle, and a stainless-steel condenser. The passage has several areas that are heated up by a condenser. The spray nozzles lie on top of each zone. The water is sprayed at differing temperatures right into the drum. The item is then poured into the closed drum.

The Tunnel & Batch Pasteurizer is a kitchen counter appliance that makes use of an electric warmth source to sterilize liquids. It consists of a pre-heated glass pitcher, a stainless steel drum, and a stainless steel tube. The gadget includes individual guidebooks and also links to a standard wall electrical outlet. The user inserts the fluid into the drum and also shuts the lid. Throughout the process, it warms up to 140 levels Fahrenheit. Once the fluid is securely heated up to this temperature level, it is cooled and cooled down.

see it here & Batch Pasteurizer system includes a pre-heated glass pitcher and also a stainless steel drum. The system additionally features a drip pan and also user's handbooks. The whole system is connected into a standard wall outlet. The water is travelled through a pre-heated condenser and then to the product. During the procedure, the fluid is heated to the desired temperature, and the item is ready to consume alcohol.

A typical Tunnel & Batch pasteurizer system consists of a glass bottle as well as a stainless steel drum with a shut cover and a condenser. Each area has drip frying pans and spray nozzles to warm and also cool down the item, as preferred. The Tunnel & Batch pasteurizer systems are convenient and also easy to use. The A&B system is made in the United States. The equipment includes an individual handbook.

A Passage & Batch Pasteurizer system contains a pre-heated glass bottle, a condenser, a stainless-steel drum, as well as a stainless steel tube. The A&B system also consists of a customer's handbook and connects into a basic wall surface electrical outlet. The device has a number of safety attributes as well as is perfect for business and also property usage. A tunnel & batch pasteurizer should last for several years, if utilized appropriately.

A Passage & Batch Pasteurizer system contains numerous components. The apparatus itself has a stainless-steel drum with a steel body and also a pre-heated glass pitcher. A T&B system also comes with an individual's handbook. A T&B systems have an electrical link to a normal wall electrical outlet. The tube is linked to the equipment using a cord and also is connected to a plug.

A Passage & Batch Pasteurizer system has a stainless steel drum, glass bottle, as well as user's manual. It is normally furnished with a wall surface electrical outlet for plugging. A T&B system likewise has a pre-heated glass paddle top. The t & B is easy to use and also requires a wall surface outlet. You can attach the system to your home's electrical system for practical power and usage.

The Tunnel & Batch Pasteurizers have two distinct advantages over various other pasteurizers. They provide regulated temperatures, while set pasteurizers do not. This indicates that you can make even more beer at the same time without having to stop the procedure. A tunnel allows you to experiment with various recipes. You can manage the temperature level and also the time it requires to finish the process. A vaporized red wine is removed from a T&B pasteurizer maker.

Exactly How To Pick The Tunnel Pasteurizers And Batch Pasteurizers For Beer & Beverage Makers?

Tunnel Pasteurizers are makers that warm products such as sodas, beer, and acid preserves to a temperature below the point at which they are safe for consumption. The containers are loaded onto one end of the pasteurizer conveyor belt and then passed beneath sprays of hot water. The water is heated at temperature levels from 60 to 100degC. just click the following internet page of the pasteurization procedure relies on the type of container. To make the process effective, Tunnel Pasteurizers are created to disinfect items as swiftly as feasible.

Large Passage Pasteurizers are made use of in commercial brewing operations. These pasteurizers warmth beer to 140F and also hold it there for a fixed time period. After the moment is up, the beer is cooled by being submersed in warm steam or splashed with cold water. A passage pasteurizer is a common part of lots of massive developing facilities. Passage pasteurizers are one of the most usual choice of pasteurizers.

Set pasteurizer systems commonly include a stainless-steel drum with a pre-heated glass pitcher. The system has a condenser, funnel, and also complementary devices. A lot of these systems are designed for household usage as well as feature customer overviews and also protected covers. Lots of also have the choice of a built-in cooling system. Along with batch pasteurizers, there are additionally tunnel pasteurizers that are geared up with steam shot.

“WHAT IS THERMAL PASTEURIZATION OF BEER AND BEVERAGES?”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) July 7, 2022

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article:https://t.co/0VAiOBKTMe

PRO Engineering / Manufacturing, Inc

414-362-1500 pic.twitter.com/eCXjPBP9xe

The various parts of a tunnel pasteurizer can affect the quality of the ended up beer. For instance, if the beer has been pasteurized too expensive, it can cause unpleasant "pasteurization preferences" and turbidity. A pasteurized beer can additionally include yeast and also other impurities that can bring about bottle bursting as well as unwanted development. Ultimately, this can affect the quality of the packaged item, the security of the customer, and your bottom line.

Since passage pasteurizers are such reliable equipments, they are used in a wide array of markets. The objective of the tunnel pasteurizer is to eliminate microbes, protect against fermentation, and preserve rack security. https://www.theatlantic.com/health/archive/2010/05/pasteurization-without-representation/56533/ go through substantial heat changes and also caustic cleansing chemicals. Additionally, damaged bottles can harm the pasteurizer. Passage pasteurizers from PRO Engineering have decades of experience in creating and also building them.

To keep track of the temperature level and time considered the packages to pass through the pasteurizer, a pasteurization system display is utilized. It is composed of hardware and software that travels with the item during pasteurization. It downloads dimensions to a laptop computer and also calculates PUs. It likewise manages the water sprays inside the passage and also can be regulated. There are various temperatures and also times for various products, so it is essential to very carefully think about the temperature as well as time needed for the product to be pasteurized.

When choosing a tunnel pasteurizer, consider its size and type. These devices can be found in a selection of sizes and dimensions, and are based on the type of product being pasteurized. Depending upon the type of food product, tunnel pasteurizers may be an important part of a production procedure. These tools eliminate germs, enzymes, and various other microorganisms that can make products risky to consume. So, choose the ideal one for your requirements.

Nanosecond Technologies' procedure includes spraying milk into a warmed chamber. The milk is then heated at a rate of 72.7 degC for 20 nanoseconds. Combined with fast depressurization, the milk is destroyed of all traces of bacteria. Business MST plants can process approximately 240,000 litres per hr. At 4 degC, pasteurized milk has a life span of 60 days.

Historically, pasteurization was considered a black sheep method amongst tiny and also independent breweries. Independent makers believed that pasteurization was an unnecessary concession between flavor and shelf-stability. The technique appeared antithetical to the craft values when first presented. Craft beer remained to expand as well as national brands came. National circulation implied more bottles traveling longer ranges, and drinkers became extra daring with the recipes they were taking in. Despite this, the microbial load in craft beer boosted. This decreased shelf-stability and also reduced consumer self-confidence.

When Making A Decision To Purchase A Skid Guide Tree Puller, You Need To First Think About The Features You Require From The Device

First, you require to know the hydraulic flow and also weight capability of the skid guide. You likewise require to understand the pull capability of the accessory. A mismatched skid guide and also tree puller will not work together. Furthermore, you should inspect the guard for correct installment. In case you discover a missing out on security decal, you ought to replace it promptly.

There are numerous models of the skid guide tree puller. Each one is valued in a different way as well as might have different functions. It will certainly fit onto many skid steers as well as can draw trees as much as 6 inches in size. Its blades are tapered as well as can hold onto trees much better than the standard kinds. It is compatible with both steel and wood blog posts. While the tree puller is not as flexible as others, it is made in the U.S.A. as well as features a guarantee. The components are not extremely long lasting and can be conveniently stripped.

Another terrific advantage of a skid steer tree puller is its capacity to precisely draw vegetation. This device is excellent for eliminating a single tree without influencing various other plants in the location. If the ground is wet from a current heavy rain, the extraction process will certainly be simpler. Additionally, you should take into consideration the sort of soil you are dealing with. Soil with clay is harder to dig, while sand is easier to collaborate with.

As you can see, skid steers with a tree puller attachment can do lots of tasks, from tiny landscape design tasks to commercial farming. A tree puller permits you to remove large trees without reducing them. Moreover, it enables you to choose the plant you intend to draw. Although this add-on is a major addition to many skid steers, it should not be utilized for large forest cleaning. It is best for small to midsize building jobs on freely organized trees.

An additional advantage of a skid guide tree puller is that it allows someone to get rid of a tree on their own. Since skid steers have the capability to raise a tree, they can lower the price of labor. As well as if you wish to make your procedure a lot more efficient, you should purchase a skid guide tree puller. So, when you're considering buying a skid guide tree puller, make certain to locate an appropriate version.

In addition to pulling trees, you can additionally make use of the skid guide tree puller for drawing fence posts and various other plant life. The jaws are solid enough to pull out little trees, fencing posts, and creeping plants, and also destroy wooden structures. With its powerful jaws, you can do all these points quickly and quickly. You'll be glad you acquired this attachment. While it is not the best accessory for all work, it will save you effort and time.

The most effective skid steer tree puller should have a large jaw opening, which can deal with big trees and also large posts. Its security features will certainly protect you from injury if a tree falls on you. And, grapple for skid steer ought to have top quality hydraulic cyndrical tubes and steel tree saws. So, if you're intending on utilizing it for a very long time, you ought to get one that can maintain you risk-free. However what regarding its price?

Besides bring up big trees, skid guide tree puller add-ons can likewise be utilized to eliminate fencing articles. Pulling up fencing articles is a tedious task that can't be done by someone alone. A skid steer tree puller add-on can draw them up promptly as well as successfully, conserving you a great deal of time. Just remember that the accessory will certainly leave marks on wood articles, however metal blog posts aren't the trouble.

A skid steer tree puller is specifically valuable when you're working with demolition jobs. Numerous construction jobs need getting rid of deep articles. A skid guide tree puller is useful in these scenarios because it can get rid of plants without damaging the ground. https://www.forconstructionpros.com/equipment/earthmoving-compact/press-release/21366104/kato-kato-to-debut-new-product-line-at-2021-world-of-concrete helps protect against ground disruption. A skid steer tree puller can likewise be utilized to get rid of stumps and also various other kinds of debris. You can utilize it for landscape design, as well, as it can quickly remove the stump.

Just How To Choose A Skid Steer Tree Puller?

When you intend to secure trees, a skid guide tree puller can be very valuable. This attachment has 4 rows of teeth that open up to 11 inches. It is suitable for smaller sized trees that are easy to pull out. Bigger trees will certainly call for more power and might need a various sort of tree puller. Right here are some pointers to choose the ideal skid guide tree puller for your requirements. Ensure it matches your skid guide as well as its hydraulic capability.

The Stinger Attachments STP-34 is an exceptional selection for drawing larger diameter trees. The 34-inch opening is huge enough to draw larger size trees and also honeysuckle. The sturdily-constructed front spade is 6"x6" and also 3/4" thick, as well as features serrated gussets for increased toughness. It is created a selection of different uses and can be purchased online.

A skid guide tree puller is specifically useful for demolition jobs. Tree pullers can swiftly and also easily remove post frameworks. A skid steer tree puller is likewise useful for removing plant life from the ground. This protects against ground disruption. With the attachment, a tree can be gotten rid of with little initiative as well as at much less expense than working with an expert. When utilized properly, a skid steer tree puller can conserve you time and money.

http://wheretoapp.com/search?poi=13986601065334704956 is not a durable accessory yet is great for cleansing rows or drawing messages. It additionally avoids stumps from growing back, and causes marginal ground disruption. The blades are tapered to much better hold trees as well as are suitable for timber and also steel blog posts. There are some drawbacks to utilizing a tree puller, however. It is not flexible enough for all kinds of trees as well as comes with a minimal components guarantee. Furthermore, the bolts are prone to stripping.

The GreyWolf(tm) skid guide tree puller add-on is universally-fit for the majority of tractor and skid steer models. This add-on is excellent for removing fence blog posts and also tree origins from land. This add-on is built of sturdy steel that is immune to deterioration. It is suitable for harsh settings, such as farm job. As well as because bucket for bobcat skid steer 's made in the U.S.A., it is highly resilient.

A skid guide tree puller is very useful for eliminating fence articles. Taking out fence blog posts is a laborious job and also can not be done by someone. Yet thanks to the skid steer tree puller attachment, you can conveniently bring up fencing posts. Fence articles are typically made from timber, so this attachment will likely leave marks on the blog posts. Metal posts can additionally be conveniently gotten rid of with this accessory. It is a time-saving device.

Another fantastic device for lowering trees is the Baumalight Mini Skidsteer Tree Ripper. This accessory can take care of trees approximately 12 inches in size and has an effective 5" x 12" cyndrical tube that produces 29 lots of force at 2500 PSI. It has a rotating pin that rotates 90 levels. It is a fantastic device for pulling out roots as well as limbs of trees. You can even use it to dig holes around tree roots.

If you are aiming to get rid of trees, you must select a skid steer tree puller with 4 rows of teeth. They are durable as well as can be made use of for pulling out tiny items, like bushes and fence posts. And also they are made in the U.S.A.. These attachments are excellent for challenging landscape design and building job. These accessories are easy to use, too. If you require to pull out a big tree, you need to go with the Boss.

The Industrial Tree Puller is one more fantastic alternative. It can get rid of brush up to 8 inches in diameter, making it an incredibly functional tool. Its open plate layout gives superior exposure for the operator, while a press bar keeps branches away from the taxicab. This device is budget-friendly as well as functional and also makes it the perfect enhancement to any kind of worksite. You can locate the right skid steer tree puller in just a couple of clicks.

Choosing The Right Skid Steer Tree Puller Accessory Depends On A Below Elements

First, ensure that the skid guide model is compatible with the tree puller. If it is, you can narrow your choices down based on compatibility. Likewise, make certain that the skid guide is capable of operating the puller. Hydraulic hoses and fittings are infamous for leakages as well as are susceptible to damages. A good quality skid guide tree puller add-on will feature a guarantee and fit a variety of skid guide designs.

A skid steer tree puller should likewise have safety guards as well as decals to prevent injuries. The security decals as well as guards must remain in good condition as well as be changed as needed. Using the skid steer tree puller when it is not secured from the elements is dangerous. Ensure that it is secure to run, as any kind of malfunction can result in injuries or fatality. https://foursquare.com/v/cl-fabrication/5b31ad429fca56002cb05354 should likewise check the hydraulic lines to make certain that they are limited as well as devoid of leakages.

The skid steer tree puller attachment is a superb device for getting rid of trees in limited areas. It can eliminate the whole root system of a tree in one pull, as well as some designs even have a spade on the front that aids collect the roots. This skid steer tree puller is ideal for a selection of procedures, as well as can help in reducing labor prices as well as time. So, what are you waiting on? Get one today!

One more useful skid steer accessory is the GreyWolf(tm) skid guide tree puller. The add-on is built of 3" square tubing and steel with an internal wall density of 3/8 inches. The skid steer tree puller attachment can be made use of on Bobcats or various other skid guides with basic universal fast accessory. It harnesses the power of the skid guide to pull a tree or blog post from a large location.

click this over here now for a skid steer tree puller is getting rid of the ground of trees and also various other plants. It can eliminate trees as well as fencing posts, as well as scrap wood and demolish wood frameworks. The skid steer tree puller likewise helps clear big areas of land for expanding crops. If you are intending to plant trees, you will certainly require to get rid of the origins and also other greenery in order to produce an extra productive location.

The commercial tree, stump, and blog post puller add-on is an excellent option for small trees, articles, and also fencings. If you're attempting to clear an entire task site or ranch, this accessory is ideal for the job. This device has the capacity to get rid of also the most difficult articles as well as fence rows. It is made from durable steel and also is extremely versatile. There's also a design that can eliminate posts made from metal.

In addition to eliminating trees and fence articles, a skid guide tree puller is an excellent device for eliminating bushes and fencing messages. Its powerful jaws can also get rid of fencing messages! Unlike a chain-pulling technique, the skid steer tree puller can be operated alone by a solitary driver. As well as, it's also more secure than chain pulling, which calls for an extra individual. If you do not intend to take the chance of getting hurt, you can purchase a skid guide tree puller online.

Prior to acquiring a skid guide tree puller, ensure you have a concept of the type of trees and also plants you're going to be eliminating. The various kinds of plant life have different origin systems. You may require to utilize a stronger attachment or perform a bit much more manual work to liberate the origins. After a hefty rain, the ground will certainly be wet and also less complicated to dig. Likewise, the soil type impacts the convenience of tree removal. Dirts with lots of clay will be tougher to dig up than those with more sand.

Tree pullers are especially helpful for demolition jobs. Lots of building jobs need the elimination of deep blog posts. A skid steer tree puller can get rid of these messages from the ground. A skid steer can additionally draw vegetation from the ground, which is terrific for landscaping. If you are working with a new construction, eliminating a roaming tree from the ground will protect against damages to the ground. As well as if you're just seeking a reason to cut down a tree, a skid guide tree puller is the means to go.

Why Skid Steers Are Versatile Building Devices?

When you want an equipment that can execute several jobs, you might want to take into consideration one of the Skid Steers readily available. These little, engine-powered equipments include stiff structures as well as a collection of lift arms, which can be affixed to a wide range of buckets as well as accessories. The Skid Steer is an optimal option for a range of various work, including cleaning snow, excavating holes, and also removing debris.

While Skid Steers have actually come to be a staple in building and construction websites across the world, their inventors have not constantly been as widely known. The first Skid Steer was developed in 1957 by 2 brothers from Rothsay, Minnesota, that were charged with creating an efficient machine to walk around his ranch. The brothers later marketed the civil liberties to their production to a neighborhood Devices Dealership, Melroe Production, and also started automation.

Along with being used in construction sites, Skid Steers are additionally useful in ranch work, especially in constrained areas. Add-ons for skid guides include demolition shears for removing various products. They can likewise be utilized for material handling, with a fork add-on to move pallets as well as various other items. Some skid steers are even equipped with a trencher. These versatile makers can be used to dig structures for houses, while others can doing minor demolitions and also cleaning up barns.

The ASV MAX-Series machines are crafted with a copyrighted frame, causing a high ground rate and broad separation angle. Direct-drive pumps and a fantastic cooling bundle are consisted of with these models, also. A brand-new cab design is developed to improve convenience. https://local.botw.org/Iowa/Clarinda/CL_Fabrication/1001058403.html -Series devices additionally include a boosted cab for the vehicle driver. These devices likewise come with even more functions for more comfy work.

The future generation of Skid Steers has been created with safety and security and comfort in mind. The cab is outfitted with the most effective 360-degree visibility in the industry. It also consists of a lot of creature conveniences, such as safety belt. You must additionally look for convenience as well as easy-to-use controls on the maker. The overall trip on a skid guide ought to be smooth as well as silent. This is just one of the main reasons that skid steers are so valuable in construction.

A great pointer for getting a made use of Skid Steer is to hire an auto mechanic or heavy equipment expert to evaluate it. By doing this, you can determine the high quality of the maker and also its procedure. Furthermore, you can see whether or not the controls as well as easy work efficiently, and also if the loader arms are appropriately working. By doing this, you can be certain in your purchase. It's likewise possible to rent out a skid guide if you're unclear of its functionality.

The versatility of the Skid Steer can be found in useful in a variety of scenarios. You can utilize it to move dust, rock, or mulch, along with farm chores such as grading or landscaping. There are over a hundred different attachment versions readily available, so you can select the right one for your demands. You'll be pleasantly surprised how much this functional device can do. When you buy a Skid Steer, you'll be astonished at what it can do!

A skid-steer loader is a small engine-powered machine with a stiff framework and also lift arms. Its training arms are capable of lifting a variety of pails and accessories. In addition to raising hefty tons, skid-steer loaders are additionally capable of earthwork, sweeping, and also drilling. And while these machines are frequently utilized for earthwork as well as building and construction tasks, they're likewise excellent for the demolition of buildings and also various other structures.

Used skid loader rock bucket should be inspected completely prior to acquisition. Pay unique attention to exactly how the skid-steer looks and the condition of the surrounding machinery. If the surrounding machinery is unclean or broken down, the possibilities of purchasing it are slim. For that reason, ensure you ask concerns and contrast different prices prior to acquiring a made use of skid-steer. You'll rejoice you did. Asking the vendor questions will aid protect your investment and ensure that the device is in excellent functioning condition.

Skid Steers are flexible building and construction devices that stand out at clearing huge areas of land. They can get rid of dropped trees, branches, and grass. Most of these devices are furnished with mulching add-ons that level the vegetation. Depending upon the size of the building project, medium-size skid-steers appropriate for a selection of tasks. Larger-framed models are used primarily for large-scale tasks, such as road-building as well as digging deep into. These equipments also perform well when raising hefty pallets.

Exactly How To Choose Ideal Skid Steer Tree Puller?

A skid Steer tree puller is an useful device for farmers and also landowners alike. Unlike other drawing tools, this skid Steer add-on has the ability to pull out huge trees without harming various other plants. With a greater operating capability, skid loaders are able to deal with much heavier things and are more powerful. Little trees can be easily pulled out from the base, but larger trees call for more power as well as might be more challenging to take out.

One more usage for a skid Steer tree puller is for eliminating fencing posts. This job can take a great deal of time, and also it's impossible to do it by yourself. Yet with the appropriate attachment, you can remove messages quickly and also easily. This will conserve you a great deal of time, which is particularly essential when you're working with large tasks. Simply keep in mind that while this add-on is created to pull up timber blog posts, it may also damage metal articles.

The dimension of the jaws on a skid Steer tree puller can differ from one equipment to an additional. Greater ability versions can draw larger trees, while lower capability versions are better suited for smaller trees, seedlings, as well as various other vegetation. Some even have vast jaw openings for bigger trees as well as blog posts. Another feature of the skid Steer tree puller is the guard, which stops trees from falling onto the driver. When utilized appropriately, skid Steer tree pullers can make a difficult task a whole lot simpler.

Along with removing trees from large trees, the skid Steer tree puller can additionally get rid of fencing articles and also bushes. The accessory has 4 rows of serrated teeth that effectively take out tree roots. These jaws are offered in both durable and conventional obligation designs. Read Alot more -34 is made in the United States. You can find a selection of skid Steer tree pullers online. There are also numerous testimonials on the internet that will aid you choose the appropriate one.

The GreyWolf(tm) skid Steer tree puller attachment can fit the majority of skid Steer designs. It is designed to take out fence messages and also tree origins, and is fully greaseable. These add-ons have a 3" size square tubing as well as are constructed from 3/8" thick steel. They can be installed on both tractors as well as skid Steer loaders. In addition to its capacity to take out fencing posts as well as tree roots, this attachment is also suitable with lots of other brand names of skid steers.

Among the most versatile accessories for skid guides is the fence post/tree puller. Its powerful jaws can take out origins, stumps, blog posts, rocks, and concrete blocks, and also is also ideal for getting rid of fences. The Sturdy tree puller is made from sturdy AR400 steel. Its teeth are interlocking as well as feature stiffening plates. It has an efficient clamping pressure of 3000 extra pounds.

One advantage of using a skid Steer tree puller is that it appropriates for transplanting trees as well. While this might be an additional action, it is a better alternative than excavating an opening in the ground, which can create a lot more damages. Nonetheless, if https://www.totallandscapecare.com/business/article/15042071/john-deer-introduces-three-new-backhoe-attachments are preparing to transplant your tree, you should dig around the origins to stay clear of harming the surrounding soil. There is no guarantee that the tree will certainly endure.

When running a skid Steer tree puller, always ensure to preserve the security systems. When not being used, the pail must be down. This is since the moving parts might squash individuals who are strolling under or around the device. It is also essential to keep the machine degree. It can quickly tip if you're pulling on an incline, so be sure to adhere to all safety directions. Always use a safety belt while making use of a skid Steer.

A skid Steer tree puller is a handy tool for a variety of different jobs. Several building tasks call for the removal of blog posts deep in the ground. A skid Steer tree puller can quickly eliminate articles and also plant life from the ground. In addition, it can be utilized to remove intrusive vines and also dead plant life from property. Furthermore, the skid Steer tree puller likewise has numerous other usages. The jaws of these makers can be used to shear off tree arm or legs, eliminate box thorns, as well as cut down trees.